If there is a large amount of limestone to be crushed, it also needs those machines that can handle millions tons of flow and process. The limestone jaw crusher is the most suitable for that task! This is a crushing lime rotary kiln machine that power for turning large rocks into smaller because it was manufactured as a colossal beast. The jaw crusher is a reliable and robust piece of equipment, so it does not take much time to install. A common application for the hydraulic system in such crushing hardware allows opening up be crushed when objects enter -found as solids

So a Limestone jaw crusher is used to reduce big rocks into smaller pieces. It is made up of two main parts: one stays fixed while the other moves back and forth. A specialized crusher bucket tears down the large rocks and stones as you pull it over your project. In other word, the production phase takes place in a quick and efficient manner over large scale of limestone materials.

You should always seek to buy limestone jaw crusher from manufacturers that are reliable. This quality assurance is important because it ensures the machine lasts longer and executes its work properly. Therefore, it is best to purchase from manufacturers who have received positive feedback for many years and who can prove that they produce rotating kiln high-quality machinery. If you need machines then select a trusted manufacturer and use the ones that are made with high-quality parts ensuring longevity. This investment not only saves a lot of money also increases their efficiency in the long run. Therefore, it is imperative to do some research before deciding your buy

Mining equipment can be expensive, and purchasing that machinery is often not a good investment for the job of crushing limestone. But you do not have enough money to buy all kinds of equipment, then one limestone jaw crusher is a more cost-effective solution. This unit was designed to handle the high-volume crushing output in power-saving and cost-efficient way. A limestone jaw crusher is of thick and compact construction making it convenient for operation, powering saving due to an energy efficient design. Furthermore, the design characteristics of machines cut down on wear and tear for minimal downtime due to regular repairs or servicing.

Limestone jaw crushers are highly versatile, which means they can be used in a wide range of applications. They work efficiently, deliver high output and provide reliable service. The cavities can be changed three different ways to adjust for changes in wear and application. Limestone jaw crusher can perform primary, secondary and tertiary crushing functions in course of continuous bucket conveyor production activities. They can also crush a variety of materials beyond limestone, such as granite, basalt and recycled material demonstrating their ability to effectively connect cement plants.

The evolution of limestone jaw crushers has forced companies to adopt new skills and work under difficult conditions. Makers recognized the need for technological improvement in their products to make them work more efficiently and reliably. The most significant innovation to be included in the design of a limestone jaw crusher is hydraulic systems. The system enables the crusher to run at maximum performance levels for longer periods and makes entering material with large lump sizes easier on it while keeping greater crushing power than competitors in similar size, according to Kodiak.

All in all, limestone jaw crushers are very important for the development of the construction and mining industry by simplifying its process on crushing large rocks into smaller pieces. They are efficient, reliable and cost-effective with all-around versatility and advanced design features for promoting performance. Purchasing a limestone jaw crusher for reliable manufacturers, you can be confident that the machine will last. So, if you have a lot tons limestone stone to deal with in order to save investment costs, realize that crushing plant which requires thousands of KWH consumption is not suitable. An efficient sand washer,(clinker crusher), You may find the solutions here!

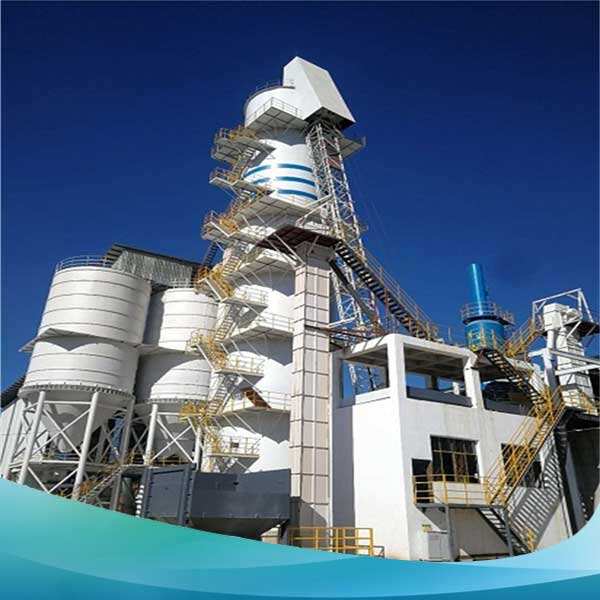

company has mostly undertaken engineering design and program design, special equipment provision well as installation and commissioning personnel training, oven services starting up furnaces, as well as production reaching of energy efficient sustainable lime shaft kiln. have built successively lime Limestone Jaw Crusherkilns that were activated with volumes 150m3,170m3 200m3, 250m3, 350m3, 500m3, etc. These were then successfully opened the effect was astonishing! Utilizing latest technology the coke lime shaft kiln the gas-burning lime shaft is kiln has been designed, and agreements design have been concluded with numerous companies.

Over past 20 years, have been committed to development, research of Limestone Jaw Crusher, production installation lime kilns its environmental protection and fully-automatic. It also low expenditure, low energy consumption so on. We are dependable for our top-quality and flawless service, and long-lasting lime Kiln.

For long time, AGICO has had professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving and environmental-protective lime shaft kiln technology perfect. It has advantages of low investment, high levels of automation, top product quality, low usage energy, long service lifespan of furnace environmental protection. has been widely used in metallurgy, non-ferrous metals, chemicals, Limestone Jaw Crushermaterials, as well as other sectors, such as deep processing as well as other industries.

AGICO a professional technical team specializes in EPC turnkey projects that cover design, manufacture installation, debugging maintenance, many other Limestone Jaw Crusher. AGICO offers a full range on-sales pre-sales services, as well after-sales technical assistance.