Carbon, specifically activated carbon, is a very unique material with roles in various daily applications. It is useful for purifying water, removing odors, and filtering the air so that it may not be harmful to breathe. This incredible substance is produced from things that contain carbon like wood, coconut shells or coal. These Cement International Engineering materials then are placed in an activated carbon kiln, where they are heated to produce activated carbon.

The process of creating activated carbon results in some pretty cool changes to the carbon materials that we use. These limestone rotary kiln kind of transformations are essential to eliminate impurities (the ones that we don´t like) and they greatly increase the surface area of the materials. A greater surface area is crucial, since the more activated carbon there is at work, the more harmful substances it can catch on to. This allows the steam or a specific type of chemical to bore holes throughout the carbon material. These minute holes, or pores, greatly increase the ability of activated carbon to cleanse and detoxify many things.

In fact, activated carbon kilns have critical applications in various industries. It is a way of producing large quantities of good quality activated carbon more easily and cheaper. Activated carbon is used by numerous companies in the cleaning of industrial effluents and drinking water, making air clean or other applications including edible oil purification, recycling chemicals from wastes or the pharmaceuticals industry.

Companies can maintain their machines and equipment in a clean state by using these lime rotary kiln special kilns while also enhancing the quality of their overall production. While it can take care of other impurities, activated carbon is best at getting rid of odors and bad tastes in water. Secondly, this Cement International Engineering material is ultra-efficient at absorbing volatile organic compounds (VOCs); a dangerous substance found in the air. In essence, activated carbon helps in purifying our environment and thus keeping it clean and healthy.

The Cement International Engineering process is called carbonization and it was where the activated carbon making begins. It is an essential part of the process. When we carbonize we heat the materials that contain carbon in an environment without oxygen. This rotary kiln lime deprivation of oxygen is especially important as it allows the materials to return to their elemental building blocks. All this leaves us with is a carbon coated burn, which is the raw ingredient to make Write activated charcoal.

After that, the char is transferred to a char activation furnace. It is the actual location of activation inside this oven. In this shaft kilns step, the char is steamed with specific solvents or chemicals. Such treatments leave a honeycomb of small holes in the material. It is this process of activation that gives the material its high degree of porosity and makes it such an effective adsorbent for trapping contaminants in water, air (see charcoal face mask) and other materials.

The maerz kiln methodology of producing activated carbon has made the leap forward technology wise, from batch-type production kilns to rotary furnace. Not only are they low-cost, but the activated carbon that is created from them provides some of the highest quality in addition to being environmentally friendly. They can even create better-activated carbon and use alternative renewable feedstocks taking the stress away from using coal/wood/bamboo for high quality activated carbon.

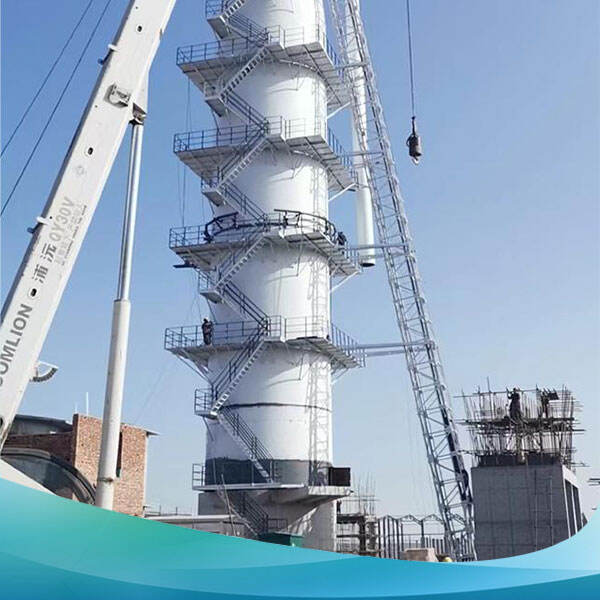

company has focused on the design engineering design, special equipment delivery, installation Activated carbon kiln, personnel training, oven services, furnace start-up, and production reaching energy efficient environmentally friendly lime shaft kiln. We have built successively activated lime shaft kilns with volumes of 150m3,170m3 200m3, 250m3 350m3 500m3, etc. These then successfully opened and effect was impressive! The gas-burning furnace was created by using the technology that had matured in the coke lime shaft. Design contracts were concluded with several companies.

AGICO a highly skilled technical Activated carbon kilnthat specializes EPC Turnkey Projects, including manufacturing, design installation. AGICO offers full range pre-sales on-sales services, as well as after-sales technical assistance.

Over past 20 years, have been committed the research, development design, manufacturing Activated carbon kilna lime kilns and its environmental protection fully automated, low investments, a low consumption energy, etc. The lime kiln we use has long-lasting service life you can trust us because of our perfect service and high-quality lime Kiln.

For long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving environmental-protective lime shaft kiln technology perfect. technology characterized by that are low-cost investment, a superior degree of automation, high product quality, low energy consumption, long life of the furnace, Activated carbon kilnprotection. is widely used in metallurgy, nonferrous chemical, metals, construction materials, as well as other industries, deep processing industries as well as other industries.