Limestone is a common sedimentary rock found in many parts of the world. It is a vital product used in the construction of homes and for mining purposes. Limestone Crusher: One of the ways to utilize limestone. This small device takes large blocks of limestone and segregates them into tiny bits that are referred to as aggregate. Because Aggregate is being consumed in many kinds of construction, and mining projects so it is very useful to serve. In this guide, we will tell you everything about limestone crushers, such as how they work, why choose a limestone crusher in construction and mining, types of limestone crushers available in the market, factors to consider when buying a limestone crusher, and how to maintain the equipment.

A limestone crusher is a device specifically designed to crush large rocks into smaller pieces, along with Cement International Engineering's product bucket elevator cement plant. The process is beneficial because it generates a top quality aggregate required for manufacturing and mining. The process begins after the stone is dumped into the primary jaw crusher. Through the door, the machine smashes these huge lumps to pieces. This crushed limestone is then sieved after which goes by a screening course of. This keeps the bits from being broken further, and all the parts that are too large to use is taken out. This makes sure that only the pieces of limestone that fit with construction or mining projects are available.

The use of a limestone crusher in construction and mining operations is one of many beneficial uses. One of the main benefits that it offers is that, in theory at least, it can bring down the cost of construction commodities. Limestone is used in a broad range of general construction applications including residential and commercial complexes, roads, bridges, dikes, on some landscapes. When companies use a limestone crusher, they are able to minimize the size of their limestone. This allows for those businesses to save on materials, which is a plus.

A further benefit to using a limestone crusher is that it can help preserve the environment, same with the electric rotary kiln built by Cement International Engineering. Sometimes mining can have a bad effect on nature and the environment. But when they utilize a limestone crusher, it can influence how much mining needs to take place. This will also help save the natural environment by protecting wildlife-rich areas from activities that might harm or destroy them. Companies and organisations can help to maintain a more sustainable planet, working to diminish the impact of mining operations.

Cone Crushers: They are used to crush rocks between two conical surfaces, which is something that a person can do when working on them, the same as Cement International Engineering's bucket conveyor belt. Their material is ground wide use a means such as the crusher and other application in the construction and mining industry.

Extending the life of limestone crusher is a very important question for all people represented in this area, as well as the vertical lime kiln by Cement International Engineering. Just as in the example of these tools cars are machines, and any machine that you have must be tended to for them to run properly. In this article, I will share some tips to maintain the limestone crusher.

Businesses that use a high-quality and capable crusher can reduce the cost of production which will improve sales in the long run, also the Cement International Engineering's product such as small bucket elevator. A robust and reliable crusher is able to process more material for growing production. A more robust crusher can reduce maintenance and replacement costs, protecting your production and minimizing downtime, which in turn results in higher availability and lower costs. This greater efficiency can result in the completion of even more projects on schedule as well as on budget.

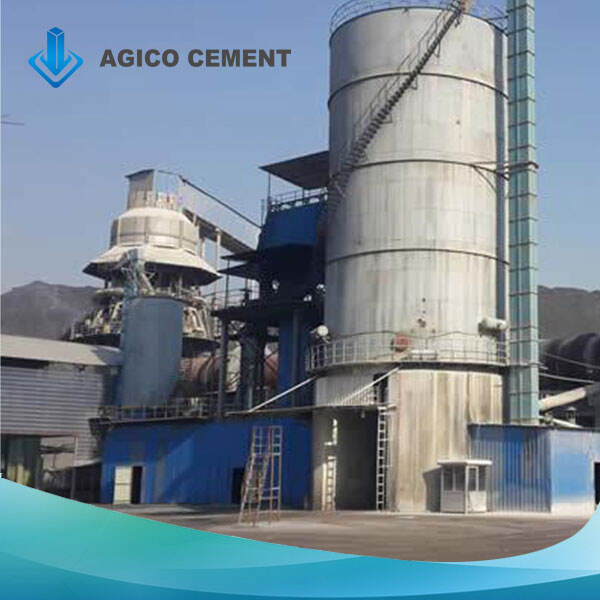

company has been involved in design of programs, engineering design, special equipment provision, installation and commissioning, oven training employees starting up furnaces, as well as production reaching of an energy-efficient and sustainable lime shaft kiln. company has built activated kilns with various sizes that include 150m3, 170m3, 200m3, 350m3, 500m3, etc. kilns were opened successfully and produced stunning effect! Utilizing Limestone crusher that is mature in the coke lime shaft kiln the gas-burning lime shaft is kiln has been developed, contract agreements have been signed withnumerous companies.

Over past 20 years, have been committed to development, research of Limestone crusher, production installation lime kilns its environmental protection and fully-automatic. It also low expenditure, low energy consumption so on. We are dependable for our top-quality and flawless service, and long-lasting lime Kiln.

AGICO a highly skilled technical team specializes in EPC Limestone crusherProjects, including design, manufacture installation. offer a complete pre-sales, on-sales, after-sales service, which provides technical support needed meet needs.

For long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving environmental-protective lime shaft kiln technology perfect. technology characterized by that are low-cost investment, a superior degree of automation, high product quality, low energy consumption, long life of the furnace, Limestone crusherprotection. is widely used in metallurgy, nonferrous chemical, metals, construction materials, as well as other industries, deep processing industries as well as other industries.