Quick lime kilns are a prime example of this in the industrial processing world, serving as critical facilities that take raw lime rotary kiln limestone and process it into a useful product with incredibly high reactivity-quicklime. It is a process in place since ancient times perfected with modern technology and remains highly instrumental for various industries from construction to environmental management. Quicklime, the common name for calcium oxide (CaO), is of such usefulness that it has been invented and reinvented over tens of millennia. So many uses in so many filled require a chemical formulation on its orderFew chemicals have even Fist with as clear an historical hundred or thousand years side quick stone Load up the Lime: What Even Is It? In this article, we take a deep dive into the fast lime kiln operations - their benefits, tactics to improve production efficiency & ecological parameters as well as real-world case studies across different industries.

From Wikipedia: Advantages of **shaft kilns** to rotary tube divorces have the following Quick lime spice up offers a series among advantages upwards traditional kettle designs. For starters, they will deliver better fuel economy by utilising LTE-combustion shaft kilns systems which can cut fuel use hence operational costs. This process is important for products that must enter into a reaction with other materials, and can lead to variation such as the purity of raw ingredients in this case obtaining through controlled processing allows material without dressing being added (as well reducing pollution) What is more, contemporary fast limestone ovens are developed to promptly alter as automobile feeder premier likewise the developing demands. And, in an increasingly volatile market environment, the investment becomes future-proof by being capable to adapt rapidly and effectively as industry need.

Automation And Control Systems At The Core Of Quick Lime Kiln Optimization With sensors, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems developed into them, these modern kilns can provide full-time monitoring for temperature control as well as lime shaft kiln material flow to save energy. As a result of concentrating on preserving optimum flexibility during the calcination operation, these systems provide waste minimisation as well as greater throughput potential while ensuring constant end product quality. By not only alerting operators when potential malfunctions are about to occur, but also by providing predictive maintenance operations alike which can prevent these outrages before they happen in the first place.

AND, today environmental consciousness is not just a nod to the past or an after-market add-on but serves as its guiding principle. Smarter quick lime kilns to meet modern needs by using environmentally friendly technology with low emissions and sustainable turn-key solutions. For example, some kilns take advantage of the exhaust heat and use waste recovery systems to harness this energy for other purposes which reduce carbon footprint. Moreover, the use of sophisticated filtration systems also ensures compliance with a multitude of environmental regulations for dust and emissions. In terms of eco-friendliness in lime production, the use of alternative fuels such as biomass or waste gases is another aspect which highlights this dedication.

Quick lime production process starts with the feeding of crushed limestone into the kiln, where it is heated to above 900⁰C by direct fire and completely burned. That surfaces surround fastest air-infusion which burns easily. at such high temperatures carbonate minerals decompose releasing carbon dioxide (CO2) gas CaO + CO3 =CaCo3 /SDT/). The rotating motion of the kiln helps to ensure even heat distribution and gas exchange. After the quicklime has been calcined, it is cooled either to slake water and produce hydrated lime or is taken straight to use. During the processing, attention needs to be given at temperature control and residence time so both quality of product and safety is maintained.

over 20 years, we've been devoted development, research, design, production, installation of lime kiln which is a green kiln and fully-automatic. is also low investments, a low quick lime kilnenergy and more. can be trusted for our top-quality flawless service, as well as long-lasting lime kiln.

AGICO a highly quick lime kilntechnical team, which specializes in EPC turnkey projects, which include manufacturing, design installation, debugging maintenance, other services. provide comprehensive pre-sales, after-sales and after-sales service system, providing technical support needed meet requirements customers.

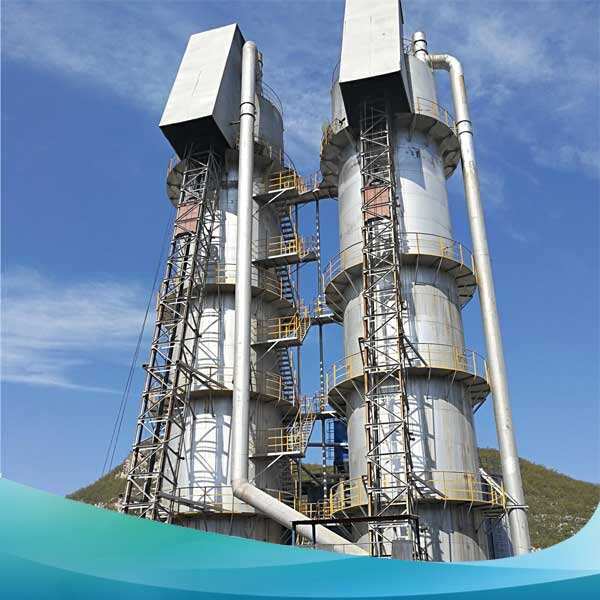

For long time, AGICO has had professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making the energy-saving and environmental-protective lime shaft kiln technology perfect. has advantages low quick lime kiln, high levels of automation, top product quality, low power consumption, long time of furnace as well as environmental protection. has been widely used in metallurgy and non-ferrous chemical industries, metals, building materials other industries, deep processing industries other industries.

company has focused on program design, engineering design, special equipment supply as well as installation and commissioning training of employees, oven services, furnace start-up, production reaching of energy-saving and green lime shaft kiln. company has built activated quick lime kilnwith various sizes such as 150m3, 170m3, 250m3, 350m3, etc. kilns were opened successfully had remarkable effect! Utilizing advanced technology of coke lime shaft kiln the gas-burning lime shaft furnace has been developed, and agreements for design have been concluded with numerous companies.