What Type of Machine is a Roller Mill? As a result, if you are employed in the grain sector you probably understand how beneficial this machine could be. A cement vertical roller mill machine is a useful tool to help farmers grind various types of grains such as wheat, corn and barley into flour. This flour is then utilized to create different wonderful foods such as bread, pasta or other yummy treats. Through this text, we will come to know that how it works of roller mill machine, how roller mill machine make us efficient work and help for making highly quality flour.

A roller mill machine operates by crushing the grain among two cylinders that rotate horizontally and are separated by differentially formed rollers. These cylinders rotating at different speeds provide a strong grinding effect. The grain passes through and gets crushed in the milling process, producing fine powder particles. This powder is then further grounded to a fine texture which is what we use for baking and cooking. Works very fast The first major pro of using the roller mill machine is that it can work quickly. In this way, you can get more flour in less time so that the farmers and bakers have a problem to keep up with the demandONUS!

A rolling mill machine ultimately takes your granulated state and transforms that into the best manageable flour. This post contains affiliate links and I may receive commission, at no cost to you, if you make a purchase through one of them. We use only our own roller mill machine, so we are able to deliver consistent high quality flour every time. When you are baking bread or making pasta, this consistency comes in very handy. High quality flour is important to make delicious food that will cater to the masses!

If you need to up your grain processing game, it might be time for a roller vertical cement mill system upgrade. These new machines are supposed to be more energy efficient and faster compared to standard models. Advanced roller mill systems sometimes come with automatic feeders to further save time and reduce waste (Altuntaş, 2012). So you are able to spend more time on your baking and cooking rather than worrying about the milling process.

This is the greatest thing about roller mill machines — they can be adjusted to your specific needs. What that suggests is that you are able to tweak and customize the maker to fulfill your demands. You could specify larger cylinders and any number of styles for the rollers, just to name a few options. The flexibility makes it simple to meet the needs of every type of operation a roller mill is needed for, whether you are grinding barley, corn, or wheat. Whether working with unique or simple requirements, customizable machines can give you the best results when processing your grains.

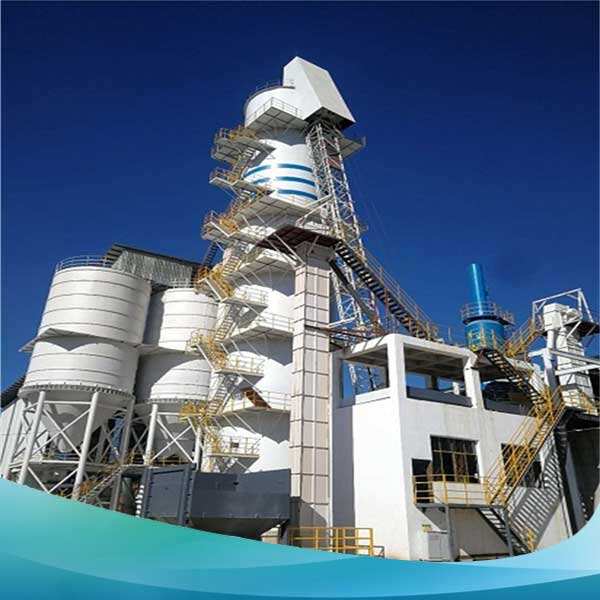

AGICO a highly skilled technical Roller mill machinethat specializes EPC Turnkey Projects, including manufacturing, design installation. AGICO offers full range pre-sales on-sales services, as well as after-sales technical assistance.

company has been involved in design of programs, engineering design, special equipment provision, installation and commissioning, oven training employees starting up furnaces, as well as production reaching of an energy-efficient and sustainable lime shaft kiln. company has built activated kilns with various sizes that include 150m3, 170m3, 200m3, 350m3, 500m3, etc. kilns were opened successfully and produced stunning effect! Utilizing Roller mill machine that is mature in the coke lime shaft kiln the gas-burning lime shaft is kiln has been developed, contract agreements have been signed withnumerous companies.

Since more than 20 years, we've been involved research, development, design, production, installation lime kilns that Roller mill machinefriendly fully automated, low investment, energy consumption is low, etc. are trusted for our excellent reliable service, and long-lasting lime Kiln.

For long time, AGICO has had professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making the energy-saving and environmental-protective lime shaft kiln technology perfect. has advantages low Roller mill machine, high levels of automation, top product quality, low power consumption, long time of furnace as well as environmental protection. has been widely used in metallurgy and non-ferrous chemical industries, metals, building materials other industries, deep processing industries other industries.