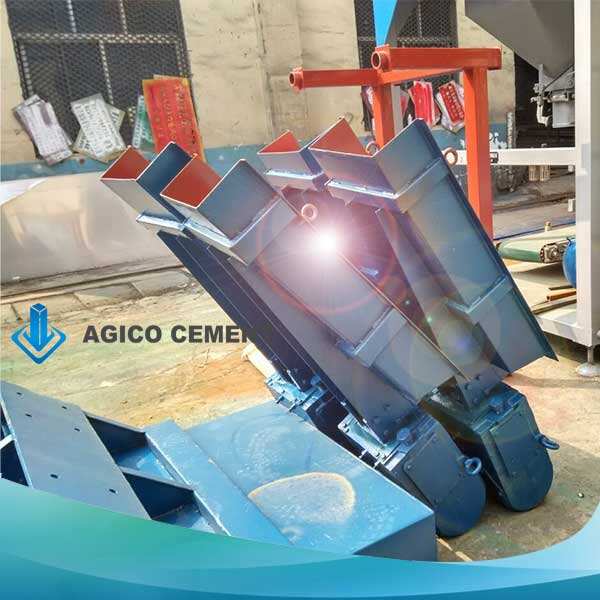

In a world of machines, there lived one machine -A Vibrating Feeder Hopper. The miracle of this machine was developed by Cement International Engineering company. After all, it is meant to move different materials from particular location to one another So today, we are here to talk about a wonderful gizmo and its working.

Vibrating feeder hopper is a special machine which is very useful because it moves all types of materials by shaking. Think of a giant box with the bottom shaking so fast! This shaking motion is beneficial for driving and carrying the materials present in the hopper. Vibrating feeder hoppers are used to move rocks in most mining sites and to help with processing grains and other ingredient in food factories.

The vibrating feeder hopper is used for a lot of good things that make it quite useful. For starters, it moves materials at great speed. This is valuable because it saves time when businesses need to get materials from A to B. Secondly, the great advantage of this machine is that it can carry many types of materials. The dry-screw feed system can handle everything from small wheel gravel to large solid metal blocks. Ultimately, the vibrating feeder hopper can be customized in sizes to meet individual business requirements. A company requiring a vibrating feeder hopper that is larger or smaller, can order one to be the exact dimensions they need.

So now, you may be wondering how exactly will a vibrating feeder hopper work? It causes the machine to shake from it bottom, when you place materials carefully into the hopper. This shaking action will make the materials move forward and slide from the top of the distributor. There is a conveyor belt that may work along with the hopper to transfer the materials even further down sometimes. Together, this enables everything to happen smoothly and quickly and makes the whole process more effective.

feeder vibration can be a lot of different shapes and sizes, They also come in tall and thin, or short and wide. The design usually depends on what type of material is moving. Take, for instance, a business that has to move heavy blocks of metal from one end to another, then they might need a machine powerful enough and reinforced so that all the weight can be handled safely.

There are many choices as far as material is concerned when looking for a vibratory feeders. Regular materials used are either steel or aluminum, since their strength is at a very high level. For lighter materials, however, plastic can even be used in the hopper. The vibrating feeder hoppers sometimes are coated special materials to avoid getting rusty and damage over time. This additional layer of protection means the machines they are installed on will last longer and still work like new.

You can find a vibratory grizzly feeder in many different types of jobs and industries. They are extensively used in mining, where they assist to transport ores and minerals from place to another. They are also used in food factories to move grains and other substance that require processing. In construction, manufacturing and many other industries where there are moving parts (no pun intended) vibrating feeder hoppers can also be found.

more than 20 years, are committed to development, research Vibrating feeder hopperinstallation of the lime-kiln. is full-automatic with the lowest cost investment. lime kiln has an extended life span we are able to be relied upon due to excellent service high-quality lime mill.

company mainly has Vibrating feeder hopperprogram design, engineering, special equipment installation commissioning ovens, furnace start-up and production reaching create an energy-efficient, green lime shaft Kiln. constructed successively activated lime shaft kilns volumes of 150m3, 170m3 200m3, 250m3, 350m3 500m3, etc. They were opened, and the result impressive! Utilizing the advanced technology of coke shaft kiln, the gas-burning lime shaft kiln has been developed contract agreements have been signed several companies.

long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming a complete set of shaft kiln production technology management systems, making energy-saving and environmental-protective lime shaft Vibrating feeder hoppertechnology perfect. This technology has low cost of investment, high quality of automation, superior product quality. also low energy usage as well as an extended furnace life. It has been widely used in metallurgy non-ferrous chemical industries, metals, building materials, as well as other sectors, such as deep processing, etc.

AGICO a highly skilled technical team is specialized EPC Turnkey Projects. includes Vibrating feeder hopper, design and installation. offer wide range of pre-sales and after-sales support along with after-sales technical assistance.