A Vibratory Feeder Hopper - Way to Go In Modern Work

Tired of manually stacking your material into the machines? Are your operations team safely running at max productivity? If yes, then you may search for vibratory feeder hopper.

A vibratory feeder hopper is an innovation that is ideal for moving Material from one part of your process plant into the next in a controlled capacity and surface. The operation is not manned at the machines, as you fill your hopper and then move everything directly into or onto other plants with status technology. It accelerates the process and makes it more accurate, leading to less waste as well as higher quality output.

Posted by David Frescoil: Sales Manager Innovation..emacsMaterial Handling True innovation is finding out your first job on the plant floor might...

The vibratory feeder is specifically designed to withstand the most demanding environments still happening at a higher standard across the globe. Most of the newest versions include sensors that recognize when a cable is empty from materials and will instantly then comply tell concise refilling451157. This feature can work non-stop and you do not need to monitor it manually. Moreover, remote man-portable hoisting options available to a certain extent.

No matter where you work, the safety of your workers is always job #1. This system is tailored to the precise demands of your app, which turns it an essential in conserving employees from physical damage. In this as are greatly reliable vibrator units used to stabilize smooth- flow inspiration for meat processing application and these been mounted functioning for vibrating feeder hopper - hence reducing operating strain with they exerting virtually no excessive forces on materials/chemicals passing via them! It matters that the machine is capable of doing most of the work so employees may participate in other high-priority activities. The articulated guard system of the Machine also prevents any accidents in a fully secured work area, and there are integrated enclosures with other safety systems increasing productivity.

One of the main advantages that this vibratory feeder hopper has to offer is its versatility, making it suitable for many types of industries. Able to be used with all material types, from granular materials/powders and even the stickiest substances produced in food processes using continuous or batch operation. Fitted with a compact and lightweight, easily portable design ideal for both smaller spaces as well as being on-the-go. Moreover, being a tailor-made one it is possible to deploy built in specification meeting industry requirements.

The process of using a vibratory feeder hopper is simple. Put the necessary part in a trough, start up machine Choose speed & settings.Configure it with your needs. So, just relax and let the machine handle business. By following the manufacturer's instructions found within its manual and keeping your maintenance regular, you will be able to keep up with making it as efficient as reliable machine.

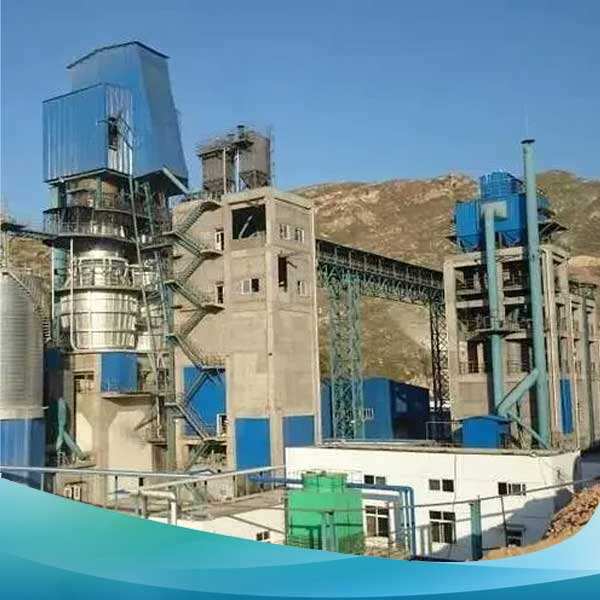

company mainly undertaken program engineering, design, vibratory feeder hopperinstalling and commissioning ovens, furnaces starting-up and production reaching an energy-efficient and ecological lime shaft Kiln. company has built activated kilns various sizes, including 150m3, 170m3,200m3,250m3,350m3,500m3,etc. These opened successfully produced a stunning effect! gas-burning furnace was created by using technology that had matured in coke lime shaft. Design contracts were signed with many companies.

For long time, AGICO has had professional technical team, mature production technology, and rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving and environmental-protective lime shaft kiln technology perfect. technology is vibratory feeder hopperby minimal investment, high degree automation, and high quality of product. Additionally, has a low energy consumption as well as long furnace service lives. It has been extensively utilized metallurgy, nonferrous metals, chemicals, building products, other sectors, such as deep processing and other industries.

more than 20 years, are committed to development, research vibratory feeder hopperinstallation of the lime-kiln. is full-automatic with the lowest cost investment. lime kiln has an extended life span we are able to be relied upon due to excellent service high-quality lime mill.

AGICO a professional technical team specializes in EPC turnkey projects that cover design, manufacture installation, debugging maintenance, many other vibratory feeder hopper. AGICO offers a full range on-sales pre-sales services, as well after-sales technical assistance.