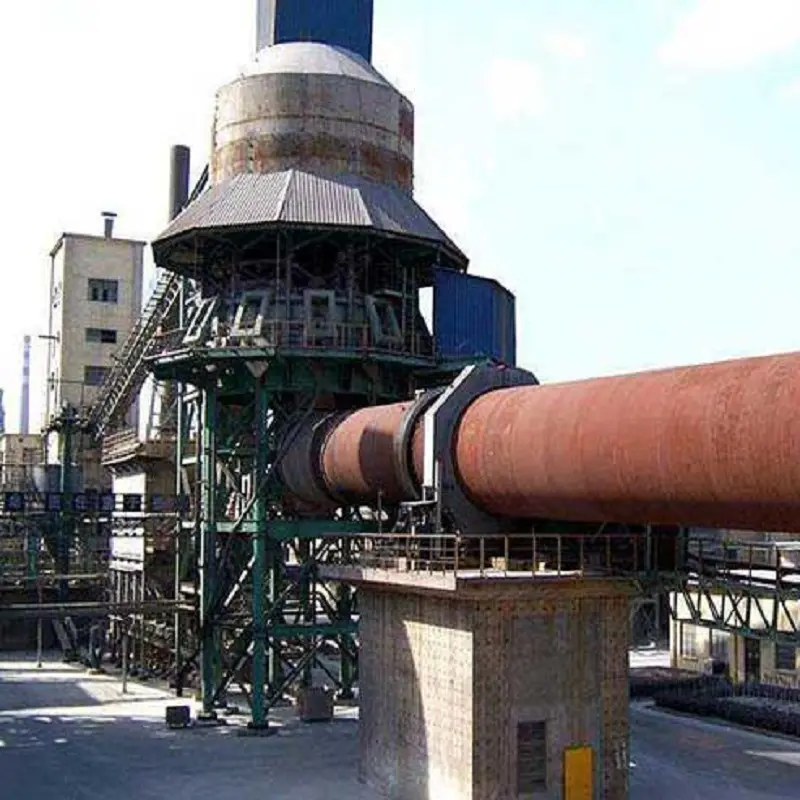

Is there a proven way to process limestone and other minerals using less crusher energy but more grinding power? Need Rotary Lime Kilns?! For the past century, these machines have been in use and on a regular basis they prove to be exceptionally capable for creating high-grade lime. Today, we shall discuss 9 reasons why going for a Rotary Lime Kiln in your plant can be the most intelligent choice you take.

Features of Rotary Lime Kilns:

Rotary Lime Kilns hold numorous benefits over the other types of kilns, and one important advantage is that they can produce lime continuously with a consistent quality. The overall refined firing municipal of burnt lime, impels that the final product retains an equal elementry accurate to either highest frame. Which brings us to the next benefit of how fast compared to any other methods opening bank account ). Ablation in an extended channel of high temperatures results accurate and fast processing.

Novelty in Rotary Lime Kilns :

In 1968, the innovation in Rotary Lime Kilns is so wonderful. All of these machines are the newest models that have available and they were all carefully designed to encourage safety, productivity. These machines feature state-of-the-art technology to ensure uninterrupted processing and better energy efficiency as well superior combustion control.

Some of the Safety features and facts about a few Rotary Lime Kilns:

Safety is a priority with Rotary Lime Kilns the safety features are built in - Safety probe for kiln tip -off,Dual-Handwheel tilt,Loud siren if Such measures involve safety guards, emergency shutdown systems, an oxygen level monitoring and a slew of other precautions such as safety interlocks on all moving parts to ensure the operator's health.

Uses and Applications:

A rotary lime kiln has many applications. They can manufacture more than just lime...cement, alumina, iron ore pellets and other - but let's stick to our main topic. The adaptability of Rotary Lime Kilns makes them a favored choice all throughout various businesses

How to use Rotary Lime Kilns:

Rotary Lime Kilns: A SIMPLE AND EASILY OPERATED SYSTEM The machines had to be fed by preparing the feed stock, preheating and loaded into the kiln. Friendly controls enable operators to simply regulate temperature and feed rate.

Service and Maintenance:

Your Rotary lime Kiln is a very valuable piece of equipment good preventive maintenance ensures long life and fabrication efficient. They are found and repaired during servicing so they do not blow up in your face. Periodical maintenance does not only make the machine safe to operate, but also allows a long-term expected lifetime of solutions full range and overall reduction in failures.

Quality of Lime Produced:

The lime quality generated in Rotary Lime Kilns is very high. Having reusable ancillary components and a zero-loss flow path results in an extremely high-purity final product. Opacity of white can be controlled by temperature and the amount of oxygen in a kiln during the firing process.

Rotary Lime Kilns Application:

Applications Of Rotary Lime Kilns Applications include cement production, iron ore pellet manufacturing and alumina applications They are widely used in the lime production for water treatment, paper mills and construction materials.

Conclusion:

What it comes down to are reliable and highly efficient Rotary Lime Kilns in processing limestone as well as the production of other mineral materials. They provide safe, versatile machines for many industries. Their reliable operation produces top quality lime that is appropriate to meet the needs of various applications. When making the decision to go with a Rotary Lime Kiln for your plant you should be investing in years of proven and reliable operation.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ