Introduction

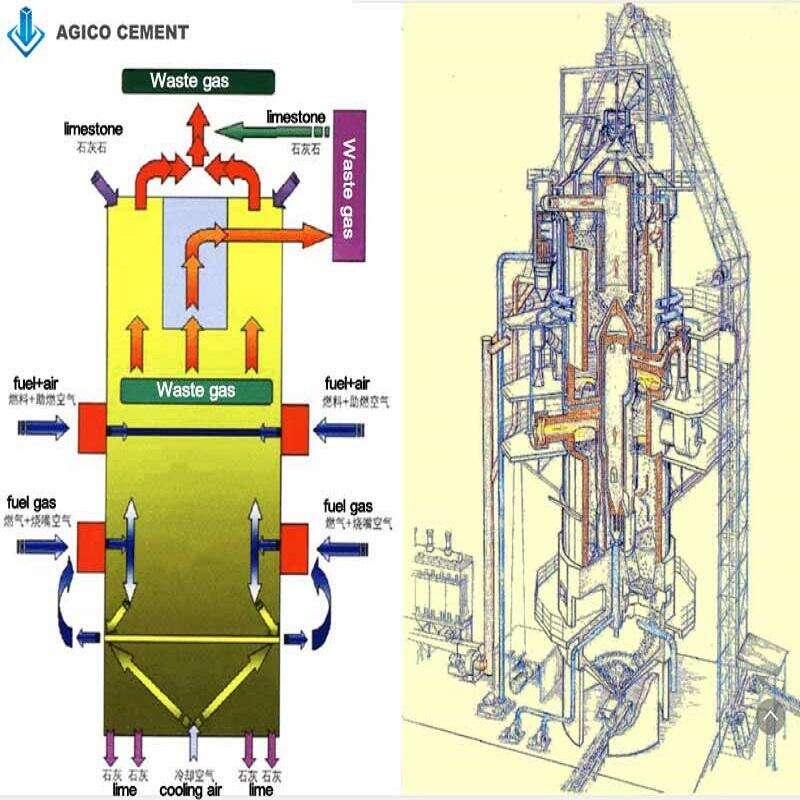

Lime kilns are essential when it comes to processing limestone into a product useful. The Cement International Engineering help to reduce the size of the material convert raw into a powdered form can be used in various applications. Vertical lime kilns, in particular, are gaining popularity due to their efficient and nature cost-effective. We will look at the five best manufacturers of vertical lime kilns and what sets them apart.

Advantages of Vertical Lime Kilns

One

of the most significant advantages of vertical lime kilns their

efficiency. They are designed to use less fuel and produce more lime per

unit of fuel than horizontal kilns. This made possible by the design of

the vertical kiln, which allows the limestone to move through the kiln

in a vertical direction, providing more heat transfer efficient.

Another

advantage of vertical lime kilns their versatility. They can be used to

process various types of Vertical Lime Kilns limestone, including high-calcium, dolomite,

and limestone magnesian. This makes them a tool useful industries are

many including the steel, paper, and construction industries.

Innovation in Vertical Lime Kilns

The

best manufacturers of vertical lime kilns are continuously innovating

to improve their products. One area of innovation in the use of

technology to monitor and control the kilns. Manufacturers are

incorporating sensors and systems are monitoring allow for real-time

monitoring of kiln conditions. This helps to optimize the kiln's

performance and improve product quality.

Another

area of innovation in the design of the kiln itself. Manufacturers are

experimenting with Lime Kilns different materials and designs to create kilns are

more efficient and safer to use.

Safety and Use of Vertical Lime Kilns

Safety

a priority top manufacturers of vertical lime kilns. They are designed

with safety features such as automatic shut-off systems and emergency

stop buttons. Manufacturers also provide safety training to their

clients on how to operate the kilns safely.

It

essential to ensure the kiln properly fueled and maintained when it

comes to the use of vertical lime kilns. The Annular Shaft Kilns limestone should be loaded

into the kiln carefully and at the right rate to ensure processing

efficient. It also crucial to monitor the kiln conditions regularly to

ensure the product lime of the desired quality.

Service and Quality

The

best manufacturers of vertical lime kilns provide excellent service to

their clients. They offer after-sales support, including maintenance and

repair services, to ensure their clients' kilns are running

efficiently. They also provide training to their clients on how to use

and maintain the kilns correctly.

Quality

another certain area where the best manufacturers of vertical lime

kilns stand out. They use high-quality materials and employ quality

strict measures to ensure their products meet the highest standards.

This ensures their clients receive a reliable and product meets are

consistent needs.

Applications of Vertical Lime Kilns

Vertical lime kilns have many applications, including in the production of lime and quicklime hydrated. Quicklime used in many industries, including the steel, paper, and chemical industries, while hydrated lime used in agriculture, construction, and water treatment.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ