Advantages OfUsing Vertical Shaft Lime Kilns

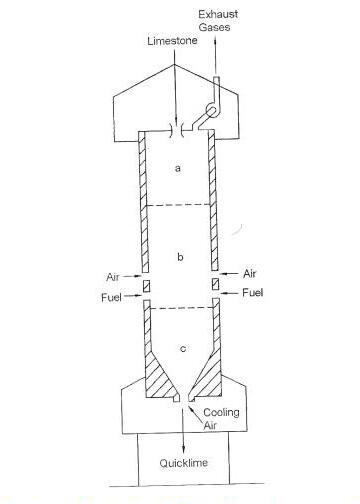

Vertical shaft lime kiln is a kind of static kiln for the calcination burning of limestone-the quality, particle size and process participle are quite different from like the characteristics working principle according to how they unfold. This technology, the vertical shaft kiln or VSK abbreviate as well and developed in China during 70's for cleaner more compact ranged production of Calcined Lime to yield quicklime going on an old but tried path.

Affordable solutions and environmental advantages

The vertical shaft lime kiln is one of the most cost savings solutions. It is more economical to install and maintain compared to the usual rotary kilns, which means that there will be a lesser amount of initial financial outlay needed. In addition, the lowered fuel and labor expenses translate to long-term operational cost savings.

Other than the financial gains, vertical shaft lime kilns also provide several environmental benefits over the prevailing rotary kinls. Characteristics of lower combustion fuel and emissions are achieved, so that the carbon output as CO2 is reduced leading to a decrease in air pollutants produced during limestone calcination in shaft kilns. Additionally, system can include a state-of-the-art dust control systems to further reduce the emission of particulate matter. These kilns also reduce the environmental impact - by using alternative and renewable fuels to produce lime, such as biomass or natural gas, vertical shaft systems enable a more sustainable production method while keeping industrial efficiency at its best.

Increase Lime Throughput

In addition, when compared with traditional rotary kilns, the vertical shaft lime furnace has higher fuel efficiency. The Kiln operates under minimized temperature and airflow conditions to deliver a steady supply of high-purity quicklime regardless, thanks to its ability to maintain control over the exact temperatures within it.

In the vertical arrangement of shaft kilns, a direct and quite intensive heat exchange process occurs between the combustion products from air-to-fuel in burners, circulating against maintaining lined refractories/alumina skins for limestone alone. As a result, lime manufacturers can scale up their production if they wish to meet higher customer demand without any compromise on stringent quality requirements.

Less Maintenance Needed

A further, useful feature associated with the vertical lime kiln is that it requires almost no maintenance. Since these operate in a vertical configuration, they do not require the manual installation of refractory bricks on regular intervals which is common to most rotary kilns.

They are made of a very simple and robust structure that requires only minimal components to work efficiently. This in turn decreases the chance of equipment failure and thus increases overall lime kiln production efficiency.

Versatility of Lime Products

The existing vertical shaft kiln quicklime applications are as different as the production conditions and raw materials available. It is one of the essential compounds used in steel manufacturing, sugar refining and wastewater treatment as well as several environmental applications.

Quicklime is used in the steel industry, as a flux agent in iron and steel production and also acts as an clearinggate while curing raw sugar. The water treatment industry relies on quicklime to control the acidity of industrial waste and agriculture provides with its function neutralizes soil pH.

On the whole, a vertical shaft lime kiln is more likely to keep your costs down and not having significant impact on the atmosphere even as providing you with improved production efficiency desire minimal maintenance an may have broad applications for virtually any sort of lime products. Vertical Shaft Lime Kiln For New Lime Production FacilityIf you own or represent a lime production facility, the following information is for...View Post

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ