While China is home to a massive and expanding lime sector. The making of houses and roads is made possible with lime, it's a white colour substance. You have oven named kilns to make lime. Here are some cool kiln technologies in use today in China!

Regenerative kiln is also the special Kilns privilege. It is very energy efficient and non-polluting. What is also pretty neat, modern computer programs are used in the kiln to make sure that everything stays at its best. There programs help ensure that the lime is of high quality!

There are also a few new ways of thinking around the production process, which ideally reduces lime's environmental impact as well. One concept is to sequester carbon dioxide by keeping it underground. For example, solar power or plants could be used for energy instead of fossil fuels. These new methods are still in the works, but they could create a shining future for lime production that is at long last clean.

China - Lime Industry Struggles With Pollution Control,Seek Efficiency Vertical mixed-feed kiln and circular shaft kiln are emerging out as kind of new technologies which save energy consumption and reduce pollution too. And, further technologies to be developed use smart machines which would find the best way of making lime and special kilns that allow for faster and more energy efficient production of top-quality lime.

Conclusively it is the greatest modernised technologies on lime production that will make bright future of Chinses Lime Production. As more and wider buildings are built, there is a need to better process lime. With all these new state of the art equipment and technologies, doubtlessly that in China we are going towards a more effective but also cheaper and greener lime industry.

As Chine is the biggest growing and consuming lime nations in world which has a important weight on euro dollar of price. Due to the construction and infrastructure development boom, lime consumption in China has been increasing at a constant pace. Lime is an indispensable material to many of heavy industries on the production line for steel, paper making; building construction. Hence, there is a need for appropriate technologies to be developed with regard of lime production which should not only conserve the other resource no-metallic or commercial grades dolomite and magnesite but also lead towards ameliorate economic growth COST EFFECTIVE AND EFFICIENT TECHNOLOGY FOR LIME PRODUCTION Lime has wide application in chemical industries.

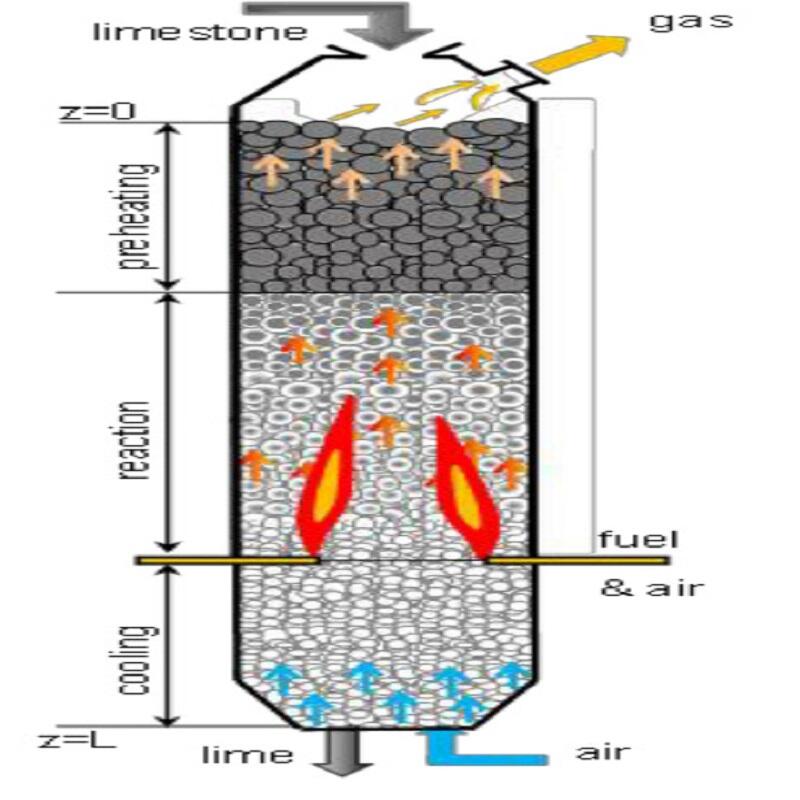

In this discussion, we will take a closer look at some of the most cutting-edge lime kiln technology that is being used to drive change within China's evolving lime market. The commonly used types of lime kiln include shaft (counter current) regenerative (SRC), mixed-feed, and fluidized bed. Regenerative kilns, which are the most technologically advanced and energy efficient.

In China regenerative lime kilns are regarded as a very important and modern technology of the Chinese Lime Industry. They are used by most of lime manufactures as its high technical and economic advantages like energy saving, optimized heat recovery, low emission profile ensured, etc. By collecting exhaust gases and using them to preheat raw materials, regenerative kilns increase efficiency of production and decrease GHG emissions.

One such pioneering technology adopted in the lime industry, China uses predictive analytics software installed on kilns. So that lime manufacturers can produce more while OTOMATIC EDGE delivers real time data on temperature, airflow and flame conditions inside the kiln... lets them stay proactive in optimizing the process. This technology helps in reducing downtime and improving quality of the product.

Emerging technologies such as carbon capture and storage, and renewable energy sources are leading the transition in China's lime industry. The carbon capture and storage technology can reduce the emission level of CO2 by capturing it from kiln flue gas, storing it underground in a safe way [5]. Moreover, the push towards more environmentally friendly lime production practices is fuelling increased contribution to renewable energy sources like solar and biomass for fossil-fuel dependent processes such as burning.

As part of an initiative to make the production more sustainable, The Vertical Mixed Feed Lime Kiln has brought new technologies for lime making. The material then undergoes the Dopol process which allows for multiple types of limestone to be fired at once and reduces emissions while increasing production. Likewise, Continuous vertical movement and feed shaft kiln technology also offers the possibility of acting as one more measure to emissions mitigation and energy saving by enhancing alternative fuel flexibility -biosyngas- into a furnace that reduces GHG.

With major advancements taking place in the lime industry across China, few leading edge technologies are expected to drive change is lime production. One such integration of artificial intelligence and machine learning algorithms in kilnswhere the ideal process will be chosen considering, which material is being processed assures to raise production efficiencyof up to a whole new level as well as quality assurance. High-temperature shaft kiln technology also enables manufacturers to make top-notch, high-calcium quicklime faster and with less energy usage for a more sustainable production approach.

From the above, we can see that the use of these advanced kiln technologies has made a tremendous difference to lime production in China. Rapid growth in construction and infrastructure development is indicative of the growing demand for more operational, reliable, and sustainable solutions to lime production requirements. The lime kiln technologies discussed above has proven potential to reduce energy consumption, decrease emissions and improve product quality. In China, new and innovative technologies are anticipated to rise that facilitates in improving efficiency, cost-effective production of lime by preserving the environment which promises a bright market for lime production.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ