VSKは非常に適応性が高く、クイックライムからグラファイトまでさまざまな材料を生産できます。低技術コスト効果があり、エネルギー効率が良く、環境に優しいクリーンな方法です。ここでは、他のどの石灰製造方法と比較しても、VSKキルンのトップ10の利点について説明します。

VSKプロセスは、あらゆるビジネスの持続可能性と能力を確保します

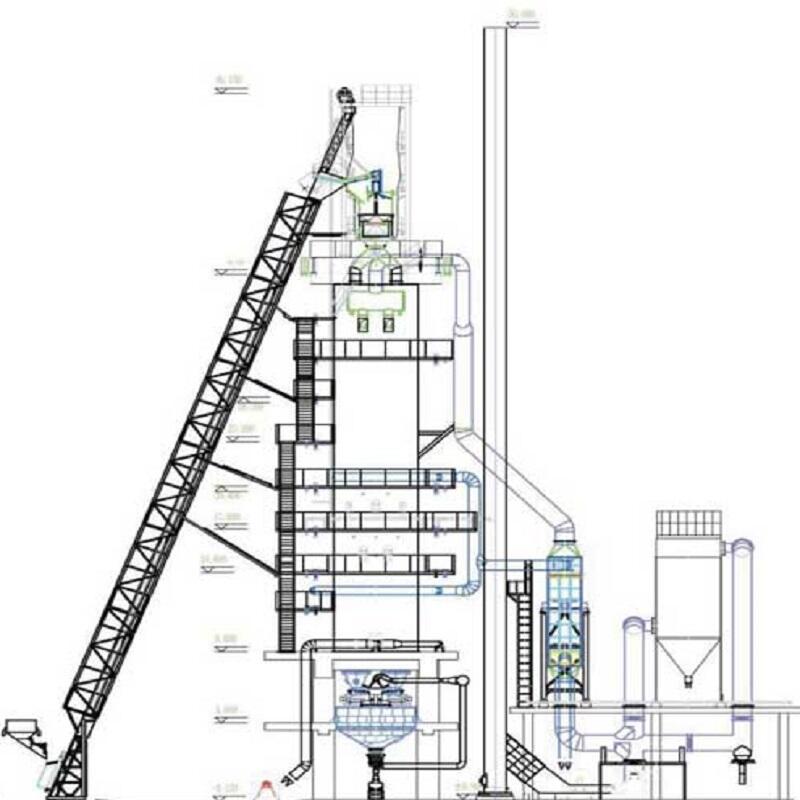

グリーンテックテクノロジーズの垂直シャフトキルンは、伝統的な回転キルンとは異なり、低品質の石炭を使用して燃焼させることができます。この革新的なプロセスは、環境への影響を抑えながらエコフレンドリーであり、伝統的な手法と比較して大幅なコスト削減につながります。

垂直シャフトキルンは、より高いエネルギー含有量の燃料を使用可能にし、熱的行为を再編して、より長く大きな鋼材に対応したり、溶融率を低下させたり、同等の燃料噴射で処理温度を上げたりすることができます。

垂直シャフトキルン(VSK)では、毎回完璧に目標を達成するキルンシステムを構築しており、これにより今後のユニットが不十分なパフォーマンスを示す余地を完全に排除します。これらの後者のキルンでは少量の燃料しか使用されず、石炭やペトコーケーなどの低コストの代替燃料も使用可能です。低熱需要により、運転中のエネルギー価格を大幅に削減でき、従って天然ガスやバイオマスと比較して理想的なビジネス目的を達成し、投資収益を最大化できます。

エコシステム保護の進展

石灰生産における持続可能性を確立する最も効果的で重要な方法は、信頼性のあるラベル付きのものとして「垂直シャフトキルン」を使用することです。これは環境問題が最優先事項となっている現在、急務となっています。バイオマス燃料を使用すると一部のガス排出量はさらに低くなりますが、巩義金馬鉱山機械有限公司が提供する融塩キルンの場合でも、植物粘土採掘に必要な土地面積は少なく、環境にやさしい技術であり、持続可能なビジネスが投資または促進できるものです。

成功へのビジネス:その解決策

優れた効率、多機能性、そして環境への配慮が特徴で、これらは高品質な石灰を競争力のある価格で生産し、持続可能な発展を代表する最良の選択肢です。急速に普及している立shaft窯についてです。これらはただエネルギー効率が良いだけでなく、すべての規模の企業にとっても魅力的な選択肢であり、それは人力の介入がほとんどまたは全く必要ないため、非常にコスト効果が高いからです。

立shaft窯 - トップ10の利点

低燃料消費: その低燃料消費により燃料コストを削減します。例えば、立shaft窯は比較的少ない量の燃料しか使用しません。

燃料の柔軟性: 窯は広範な栄養素で運転できるため、操業者は自分たちにとって安い時にボイラーを動かすことができます。

低い運営コスト: 立shaft窯はわずかな労働力で運営でき、少ない労働者を必要とするため操作が簡単です。

エネルギー節約: レオロジー乾式セメント窯は、運転に必要なエネルギーが少なく、従来の回転窯よりもはるかに経済的です。

土地と水資源の削減: 垂直シャフト窯は土地と水資源を削減し、環境に優しい可能性があります。

排出ガス削減: バイオ燃料は、少ない汚染物質を放出するため、環境に適しています。

ベストカップルは高品質石灰に関するいくつかの特許を開発しました。その垂直シャフト窯は、石灰岩の硬いセラミック製法を提供し、石油化学産業のニーズに対応できます。

用途: この炉は、速化石灰の生産やその他の化学プロセスに使用できます。

頑丈な構造: TPS Versand製造窯は、産業用仕様で設計されており、厚い鋼板で作られ、摩耗する可能性のあるピン留めドアやその他の可動部品がありません。

垂直シャフトキルンは、資本の積み上げを最小限に抑え、移動部品が少なく、回転キルンユニットよりも低い運転コストを提供します。 Rotary JoHo Pyroを追加することでユニット性能が向上します。

最終的な結論として、石灰生産において経済的で環境に優しい方法を実現するには、垂直シャフトキルン以上の適切な代替案はありません。低コストで、環境に配慮したセラミックキルンの性能とその実用価値は、環境規制への対応やエコフレンドリーな責任を果たすために製品品質の向上を考えている事業者にとって素晴らしい選択肢です。

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ